Why Wooden Privacy Fence Construction Starts with the Right Knowledge

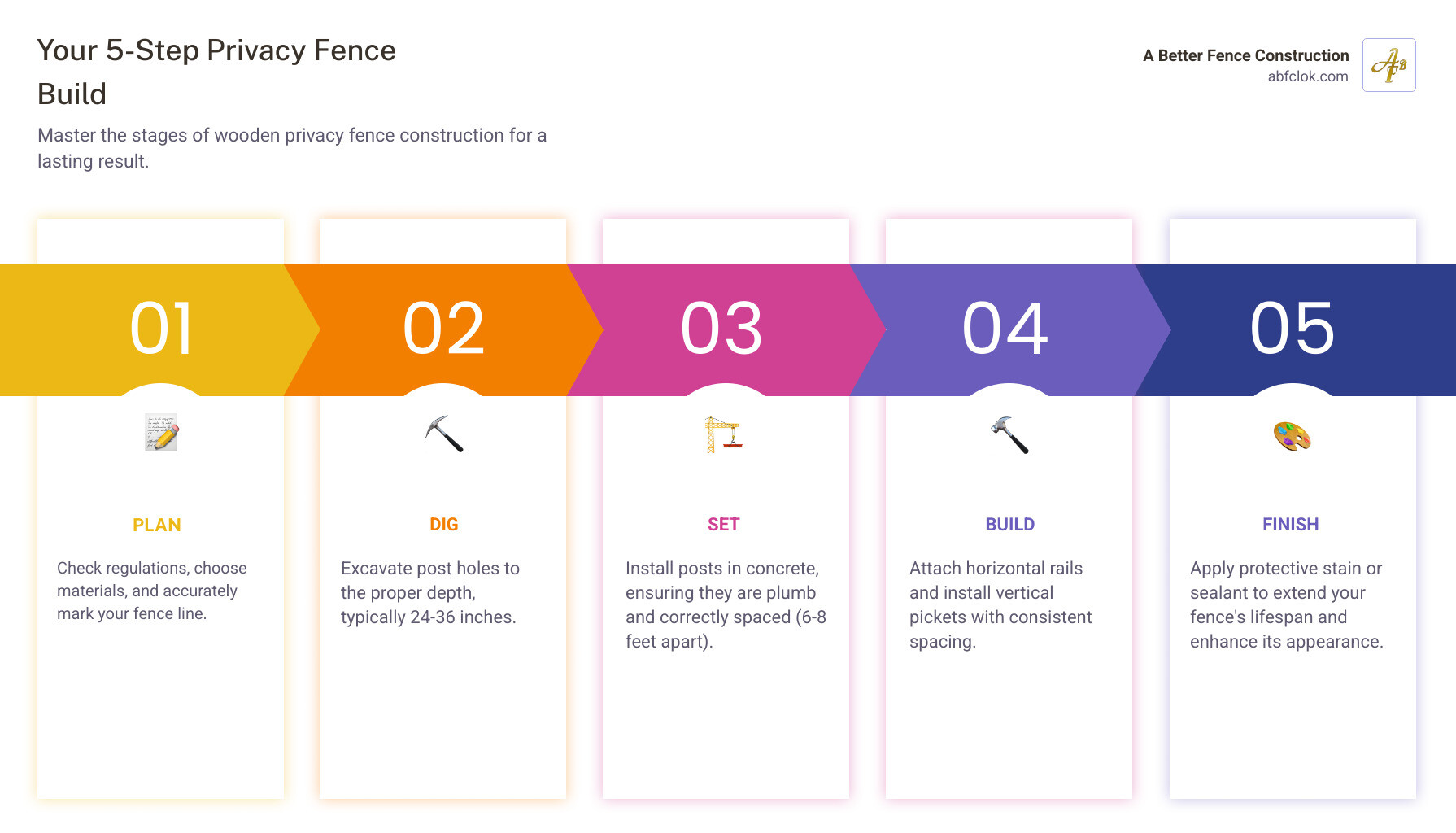

Wooden privacy fence construction is a rewarding project that adds significant privacy, security, and curb appeal to your property. While it may seem straightforward, a durable and beautiful fence is the result of a well-executed plan. At its core, the process involves five key phases, each building upon the last:

- Planning – The crucial first step where you check regulations, choose the right materials for your climate and budget, and precisely mark your fence line.

- Digging – Proper excavation of post holes to the correct depth is the literal foundation of your fence’s stability.

- Setting – This phase involves installing posts in concrete, ensuring they are perfectly plumb and spaced correctly to support the structure.

- Building – Here, you attach the horizontal rails and install the vertical pickets that form the visible barrier of your fence.

- Finishing – The final step is applying a quality stain or sealant to protect your investment from the elements and extend its lifespan for years to come.

A wooden fence does more than just define your property boundaries; it fundamentally transforms your outdoor space. It creates a private sanctuary where your family can relax and play without feeling watched, keeps children and pets safely contained, and acts as a sound buffer from neighborhood noise. A well-built fence is also a smart financial investment, often providing a strong return by significantly boosting your home’s curb appeal and overall value. As one homeowner shared after building their own fence, the project transformed their backyard from an exposed, underused yard into a true outdoor living room they now enjoy daily.

The construction process requires careful attention to detail at every stage. A small oversight in the beginning can lead to major problems later. From verifying property lines to avoid costly disputes with neighbors and calling 811 before digging to prevent a dangerous utility strike, to ensuring posts are set below the regional frost line to prevent heaving, every detail matters. Posts should never be more than 8 feet apart to guarantee the fence can withstand wind loads without sagging. Furthermore, allowing your wood to acclimate to the local humidity before installation is a professional trick that prevents unsightly warping and gaps from forming over time.

Whether you choose budget-friendly pressure-treated pine ($10-15 per linear foot), versatile mid-range cedar ($15-25), or luxurious premium redwood ($25-40+), understanding the fundamentals of fence construction is what ensures your project stands strong against the elements for 15, 20, or even 30 years.

I’m Jose Grados, owner of A Better Fence Construction. Before founding this company, I spent nearly a decade as a precision engineer in the aerospace industry. I now bring that same meticulous approach to every wooden privacy fence construction project. My background in structural design and quality control isn’t just a talking point—it means I understand the physics of building a fence that can withstand Oklahoma’s high winds and variable weather. It means every post is perfectly plumb, every line is perfectly straight, and every component is chosen for maximum durability. This engineering mindset ensures that every fence we build—whether through our professional installation or by guiding a DIYer—meets exacting standards for a beautiful, long-lasting result.

Phase 1: Planning and Preparation

Before you pick up a single tool, successful wooden privacy fence construction starts with a solid plan. Think of this phase as laying the foundation for everything that follows—it’s where you’ll avoid costly mistakes and set yourself up for a smooth build.

Checking Regulations and Property Lines

Here’s the truth: even the most beautiful fence won’t matter if you have to tear it down because it violates local codes. Whether you’re in Oklahoma City, Norman, Edmond, Moore, Piedmont, Shawnee, or anywhere in the OKC Metro area, taking the time to understand the rules is the single most important step to avoid costly headaches.

Start by calling 811—it’s free, it’s the law, and it’s absolutely essential. This service marks underground utilities like gas lines, electrical cables, and water pipes. Hitting one of these while digging isn’t just dangerous; it can lead to expensive repairs and fines that dwarf the cost of your entire fence project.

Next, check your local building codes and permit requirements. Rules can vary significantly even between adjacent communities in the OKC metro. Most areas have specific rules about fence height—typically 3 to 4 feet for front yards and 6 to 8 feet for backyards. Some municipalities require a building permit for any fence over a certain height (often 6 feet), while others don’t. A quick call to your local building or planning department is time well spent.

If you live in a neighborhood with a Homeowners Association (HOA), their guidelines often supersede city codes. HOAs can be very particular about fence style, materials, height, and even color. Getting pre-approval from your HOA is a must; failing to do so could result in fines or a demand to remove the fence entirely. Review your HOA covenants before you buy a single board.

Know your exact property lines. This might seem obvious, but boundary disputes with neighbors are surprisingly common and can become very contentious. If you don’t have a recent property survey, it is highly recommended to get one. The cost of a survey is minimal compared to the potential legal fees and cost of moving a fence that was accidentally built on your neighbor’s land. At a minimum, review your property deed and walk the line with your neighbor to agree on the boundary before any work begins.

Speaking of neighbors—have a friendly conversation before you start building. A simple heads-up about your plans can prevent misunderstandings and maintain good relationships. It also opens the door to potential cost-sharing if they’ll benefit from the new fence too. We’ve seen many projects go smoother simply because neighbors talked first.

Finally, don’t forget about setbacks—the required distance between your fence and property lines, sidewalks, or streets. These vary by location but are typically a few inches to several feet. Building inside a setback is a common code violation that can force a rebuild.

Choosing Your Fence Style and Materials

The wood you choose dramatically impacts your fence’s appearance, lifespan, and maintenance needs. Let’s break down your main options:

| Wood Type | Cost (per linear foot, materials only) | Longevity (with proper maintenance) | Maintenance Needs |

|---|---|---|---|

| Pressure-Treated Pine | $10-15 | 15-20 years | Moderate; requires regular staining every 2-3 years |

| Cedar | $15-25 | 20-25 years | Low to moderate; natural resistance to rot and insects |

| Redwood | $25-40+ | 25-30+ years | Low; naturally weather-resistant with beautiful aging |

Pressure-treated pine is the budget-friendly workhorse. It’s chemically treated to resist rot and insects, making it a practical and durable choice. The trade-off is that it requires more frequent maintenance (staining every 2-3 years) and doesn’t have the natural beauty of cedar or redwood. Because it is treated with chemical preservatives to achieve this longevity, handling it safely is paramount. You can read more about the chemicals used in wood preservatives on the EPA’s website to understand proper handling and disposal procedures. For more information about our materials, visit our materials page.

Cedar strikes an excellent balance between cost and quality. It contains natural oils (tannins) that repel insects and resist decay, making it a fantastic choice for Oklahoma’s variable climate. It can be stained to maintain its warm color or left to weather naturally to an attractive silver-gray. It’s less prone to warping than treated pine.

Redwood is the premium option, prized for its stunning natural color and exceptional durability. Like cedar, it has natural resistance to rot and insects but is generally considered more stable and longer-lasting. If your budget allows, a redwood fence is a long-term investment that can last for decades with minimal care.

Beyond wood choice, consider your fence style, as it impacts both aesthetics and function:

- A traditional board-on-board design offers complete visual privacy by overlapping the vertical boards. This ensures there are no gaps, even if the wood shrinks over time.

- Shadowbox fencing, also called a “good neighbor fence,” alternates boards on each side of the rails. This creates an attractive, identical look from both your yard and your neighbor’s, while still allowing for airflow—a great feature in windy areas.

- Horizontal slat designs provide a clean, modern aesthetic. This style often uses high-quality woods like cedar and may require closer post spacing to prevent the long horizontal boards from sagging.

- Classic picket fences are perfect for front yards where you want to define a boundary and add charm without completely blocking the view.

Think about your climate and sun exposure too. Here in Oklahoma, we experience intense summer sun, high winds, and sudden freezes. Choosing a weather-resistant wood and ensuring your design includes proper drainage and robust post setting is absolutely critical to extending your fence’s life.

Gathering Your Tools and Materials

Having everything on hand before you start saves frustrating trips to the hardware store mid-project. A complete inventory check is a hallmark of good planning.

Essential tools: A manual post hole digger will work, but for hard clay or rocky soil common in Oklahoma, consider renting a gas-powered auger to save your back and a significant amount of time. You’ll also need a 4-foot level (essential for plumb posts), a power drill with bits, a circular saw for cuts, a measuring tape, and a string line with stakes. Don’t skimp on safety equipment: a respirator or dust mask (especially for cutting pressure-treated wood), safety glasses or goggles, and heavy-duty work gloves are non-negotiable.

Materials list: Your primary materials will be fence posts (typically 4x4s, but 6x6s for gate posts), horizontal rails (usually 2x4s), and your chosen pickets or fence boards. For setting posts, you’ll need fast-setting concrete mix and gravel for drainage at the bottom of each hole. For assembly, use only exterior-grade, galvanized or stainless steel screws or nails. Never use regular interior fasteners—they will rust within a year, leaving ugly stains and compromising the structural integrity of your fence. Finally, purchase your gate hardware (hinges, latch) at the same time.

Pro tip: Always buy about 10-15% more lumber than your calculations suggest. You’ll need it to account for wood defects (knots, cracks), cutting errors, and having extra pickets on hand for future repairs.

Essential Planning for Your Wooden Privacy Fence Construction

Now comes the detail work that separates a straight, professional-looking fence from a wobbly, amateurish one. Precision here is key.

Mark your fence line with precision. Use batter boards (two stakes with a horizontal crosspiece) at the corners and run a taut string line between them. This string is your non-negotiable guide for aligning every post. Ensure it’s tight and level.

Square your corners perfectly. For any 90-degree corner, use the classic 3-4-5 triangle method, which is a practical application of the Pythagorean theorem. Measure 3 feet from the corner along one string line and make a mark. Measure 4 feet from the corner along the other string line and make a mark. The diagonal distance between these two marks must be exactly 5 feet for a perfect right angle. Adjust your string line until the measurement is exact.

Mark post locations accurately along your string line. Posts should be spaced 6 to 8 feet apart—and never more. Spacing them further apart to save on materials is a false economy; it creates weak points, allows rails to sag over time, and makes the fence vulnerable to wind damage. Closer spacing (e.g., 6 feet) creates a stronger fence, while 8-foot spacing is the standard maximum for most residential applications.

Plan your gate placement for functionality. Standard walk-through gates are typically 3 to 4 feet wide. If you need to get a lawnmower or wheelbarrow through, measure them first! Double gates for vehicle or equipment access should be at least 8-10 feet wide. Position gates in natural traffic paths and always account for the swing direction—ensure there’s enough clearance for the gate to open fully without hitting a car, a tree, or an AC unit.

This planning phase might feel tedious, but it’s where you catch problems on paper instead of after you’ve dug holes in the wrong spots. Trust me—an extra hour of planning saves days of fixing mistakes.

For details on professional wood fence installation, check out our installation services page.