Transform Your Chain Link Fence with a Simple Upgrade

Attach vinyl lattice to chain link fence for an instant change that adds privacy, curb appeal, and style to your yard. This affordable DIY project can turn a basic, see-through fence into an attractive backdrop for your outdoor space.

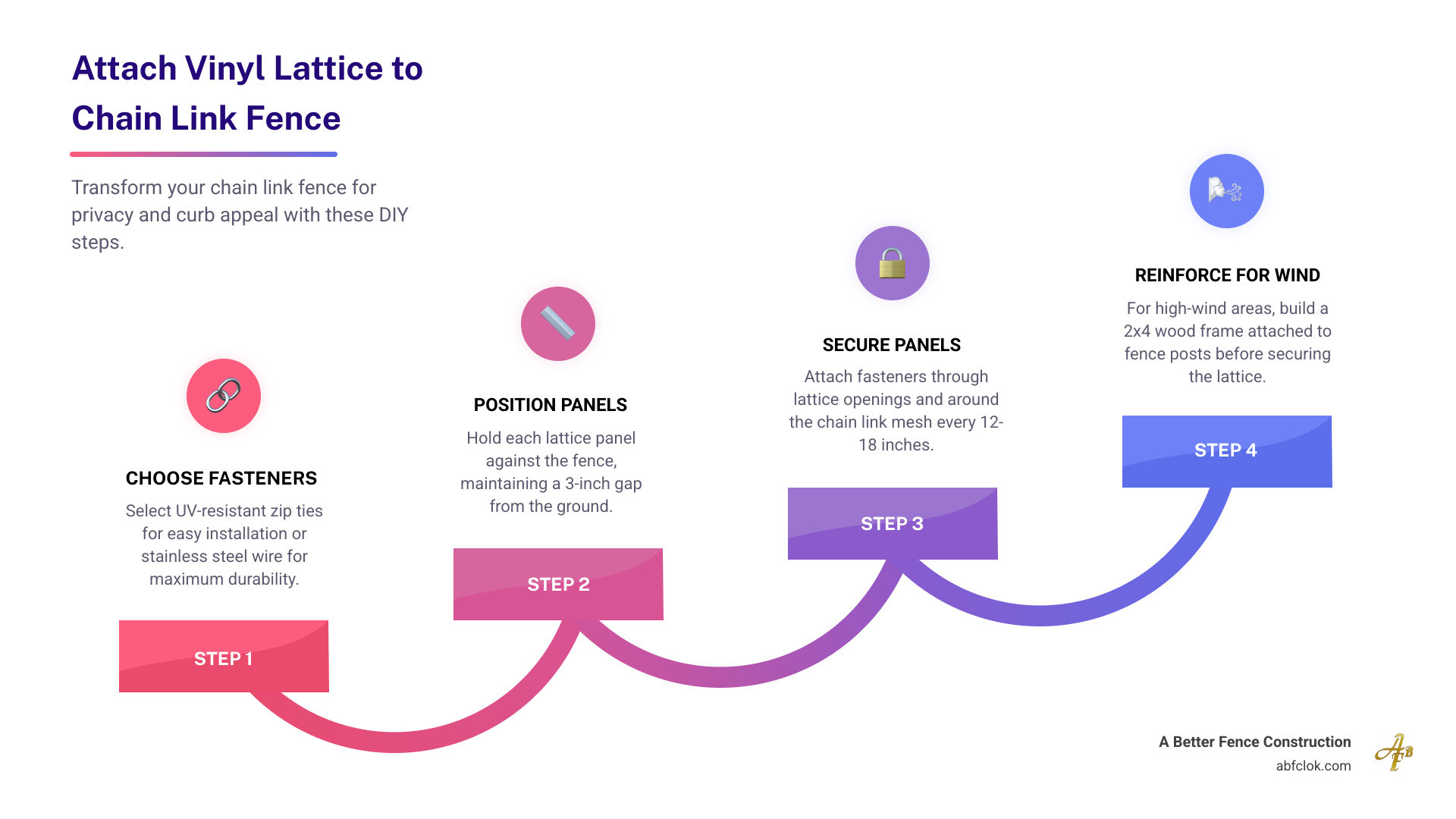

Quick Answer: How to Attach Vinyl Lattice to Chain Link Fence

- Choose your fasteners – UV-resistant zip ties (easiest) or stainless steel wire (most durable)

- Position the lattice panel – Hold it against the fence, lifting 3 inches from the ground

- Secure every 12-18 inches – Attach through the lattice openings and around the chain link mesh

- Optional: Build a frame – Use 2×4 boards attached to fence posts for maximum wind resistance

The most common method uses heavy-duty black zip ties because they’re UV-resistant, affordable, and easy to install. For windy locations, stainless steel wire (14-gauge minimum) or galvanized fabric ties provide superior durability. Pre-drilling holes in the lattice prevents cracking during installation.

I’m Jose Grados, owner of A Better Fence Construction, bringing nearly a decade of precision engineering experience to every fencing project. My background in aerospace structural design and quality control means I know exactly what it takes to attach vinyl lattice to chain link fence in a way that’s both secure and long-lasting, applying the same exacting standards used in manufacturing to residential fence upgrades. Whether you’re tackling this as a DIY project or need professional installation, understanding the proper techniques ensures your lattice panels will withstand Oklahoma’s weather conditions for years to come.

Attach vinyl lattice to chain link fence vocab explained:

Why Choose Vinyl Lattice for Your Chain Link Fence?

A plain chain link fence install can be functional, offering security and a clear boundary, but let’s be honest, it often lacks the visual appeal and privacy many homeowners desire. That’s where vinyl lattice comes in, offering a fantastic blend of aesthetic improvement, practical benefits, and long-term value. It’s a popular choice for good reason, changing utilitarian into utterly charming.

The Aesthetic Change

Imagine stepping into your backyard and seeing a lush, green wall of climbing plants or a crisp, clean white barrier instead of the stark metal lines of a chain link fence. Attaching vinyl lattice immediately lifts the look of your outdoor space. It takes your fence from an industrial, purely functional barrier to an inviting backdrop for your garden, patio, or play area.

Vinyl lattice panels come in a variety of appealing designs, from simple square and diamond patterns to more intricate options. This variety allows us to customize the look to match our personal style, whether we prefer a traditional charm or a more modern aesthetic. With options from companies like Acurio Latticeworks, we can find the perfect design to complement our home in Oklahoma City or Edmond. It’s about creating a visual screen for unsightly areas or utility boxes, or simply adding a touch of elegance that improves curb appeal.

Durability and Low Maintenance

One of the biggest advantages of choosing vinyl lattice is its remarkable durability and low maintenance requirements. Unlike wood, vinyl is engineered to resist rot, warping, and insect damage. This means we won’t be spending our precious weekends in Norman or Moore scraping, painting, or staining. Vinyl fences and lattice typically only need occasional cleaning to look their best. A quick wash with soap and water, or even just a spray with a garden hose, is usually enough to keep them sparkling. For tougher stains, a non-abrasive cleaner can do the trick. This effortless upkeep saves us time and money in the long run, making vinyl a smart investment for any homeowner in the OKC Metro area. It’s built to withstand the elements, ensuring a long-lasting and attractive addition to our property.

| Advantage | Privacy Level | Cost | Durability | Installation Ease |

|---|---|---|---|---|

| Vinyl Lattice | Semi-Private | Moderate | High | Moderate |

| Chain Link (Bare) | Low | Low | High | Easy |

| Wood Fence | High | High | Moderate | Moderate |

Planning Your Project: Materials and Tools

Before we dive into the exciting part of changing our chain link fence, a little planning goes a long way. Gathering our materials and tools beforehand ensures a smooth and efficient installation process. Think of it as preparing for a successful mission – we wouldn’t want to be halfway through and realize we forgot the crucial “thingamajig”!

Choosing Your Lattice and Fasteners

The star of our show is, of course, the vinyl lattice. These panels are typically available in standard sizes like 4’x6′ and 4’x8′. When selecting, consider the pattern – square and diamond are common, but more decorative options exist. We also want to ensure we choose a high-quality vinyl that will stand up to Oklahoma’s diverse weather.

For fasteners, durability is key, especially given our region’s sometimes windy conditions. We have a few reliable options:

- UV-Resistant Zip Ties: These are often the easiest and most popular choice for attaching vinyl lattice to a chain link fence. They’re quick to install and come in various lengths and strengths. Always opt for black ones, as clear units are not very UV resistant and can become brittle and break after just a few months of sun exposure.

- Stainless Steel Wire: For a more robust and long-lasting attachment, especially in windy areas like Shawnee or Piedmont, 14-gauge stainless steel wire is an excellent option. It won’t rust and provides a very secure hold.

- Galvanized Fabric Ties: These heavy-duty ties can be found in the chain link fence section of hardware stores. They offer another durable, weather-resistant solution for securing the lattice.

When considering attachment points, think about the spacing. Securing the lattice every 6-12 inches around the perimeter and at key points across the panel will provide optimal stability.

Essential Tools for the Job

Having the right tools makes any DIY project a breeze. For this project, we’ll need:

- Drill with appropriate bits: Essential for pre-drilling holes in the vinyl lattice to prevent cracking.

- Pliers or wire cutters: For tightening and snipping excess wire or zip ties.

- Tape measure: For accurate measurements of our fence sections and lattice panels.

- Level: To ensure our lattice panels are installed straight and even.

- Safety glasses: Always protect our eyes from flying debris.

- Work gloves: To protect our hands during the installation.

- Saw (optional): If we need to cut lattice panels to size. A fine-tooth blade is best for vinyl.

- Trim boards (optional): If our fence top isn’t perfectly level, trim boards can create an even surface for a cleaner, more professional look before installing the lattice.

How to Attach Vinyl Lattice to a Chain Link Fence: A Step-by-Step Guide

Now for the fun part: getting that lattice onto our fence! We’ll cover two primary methods to attach vinyl lattice to chain link fence, allowing us to choose the best approach for our needs and local weather conditions.

Step 1: Prepare Your Fence and Workspace

Before we start attaching anything, a little preparation ensures a smooth process and a lasting result.

- Inspect Your Fence: We need to make sure our existing chain link fence is in good condition. Check for any loose posts, sagging sections, or damaged mesh. If our galvanized chain link fence has any structural issues, it’s best to address those first. The added surface area of the lattice will put more stress on the fence, especially in windy conditions.

- Clean the Fence: Give the chain link fence a good cleaning to remove any dirt, grime, or mildew. A simple hose down or a scrub with a brush and mild detergent will suffice.

- Measure Fence Sections: Accurately measure the height and width of the sections where we plan to install the lattice. This will help us determine how many lattice panels we need and where we might need to cut them. Remember to account for a 3-inch gap from the ground to prevent moisture wicking and rot (even though vinyl doesn’t rot, it keeps the panel cleaner).

Step 2: The Direct Attachment Method to attach vinyl lattice to a chain link fence

This is the simplest and most common method, ideal for homeowners looking for a straightforward DIY solution.

- Position the Panel: With the help of a friend (or a couple of clamps), hold the first vinyl lattice panel against the outside of the chain link fence. Ensure it’s level and positioned with that crucial 3-inch gap from the ground.

- Pre-Drill Holes: This is a vital step to prevent the vinyl from cracking. Using our drill, carefully pre-drill small holes through the lattice where we intend to place our fasteners. Space these holes approximately every 12 to 18 inches around the perimeter of the panel and at a few points across its face for extra stability.

- Secure with Fasteners: Thread our chosen fasteners (UV-resistant zip ties, stainless steel wire, or galvanized fabric ties) through the pre-drilled holes in the lattice and around the chain link mesh.

- Tighten and Trim: Pull the fasteners taut, ensuring the lattice panel is snug against the chain link fence without bowing or warping. Snip off any excess zip tie or wire for a clean finish.

- Repeat: Continue this process for each subsequent lattice panel, ensuring consistent spacing and alignment. If we need to cut a panel, measure carefully and use a fine-tooth saw for a clean edge.

Step 3: The Frame Method for Maximum Wind Resistance

For areas prone to high winds, or if we simply desire a more finished and robust look, building a simple wood frame can provide superior stability. This method essentially creates a rigid structure that the lattice attaches to, which then attaches to the chain link fence posts.

- Build the Wood Frame: Construct rectangular frames from pressure-treated 2x4s or similar lumber, sized to perfectly fit each vinyl lattice panel.

- Attach Frame to Fence Posts: Use heavy-duty U-brackets or panel fixing brackets to secure these wooden frames directly to the existing chain link fence posts. This creates a solid anchor point. If our chain link posts are not perfectly aligned, we can use trim boards to create an even surface for attaching the frame.

- Secure Lattice to the Frame: Once the wooden frames are securely in place, we can then attach the vinyl lattice panels to these frames. This is best done using exterior-grade wood screws (¾” to 1 ¼”) or stainless steel brad nails. We can also use vinyl U-channel around the edges of the lattice panels to create a finished look and then screw through the channel into the wood frame for a very clean and secure attachment. This method effectively encapsulates the lattice, protecting its edges and providing a neat appearance.

Important Considerations and Potential Challenges

While attaching vinyl lattice to a chain link fence is a rewarding project, it’s wise to consider some important factors to ensure its success and longevity, especially given the dynamic weather in our Oklahoma communities.

Managing Wind Load and Structural Integrity

One of the most crucial aspects to consider is how the added lattice will interact with wind. Vinyl lattice, despite its open pattern, significantly increases the surface area of our fence. This can create a “sail effect,” putting considerable stress on the existing chain link fence posts and structure.

- Sturdy Posts are Paramount: If our chain link fence posts are old, loose, or not deeply anchored, they may not withstand the increased wind load. We need to ensure the posts are sturdy enough to support the added weight and wind resistance of the lattice. In some cases, reinforcing existing posts or even adding new, stronger posts might be necessary.

- The Frame Method’s Advantage: The frame method (Step 3 above) offers superior wind resistance because it creates a more rigid structure that distributes the wind load more effectively across the fence posts.

- Proper Fastener Spacing: Regardless of the method, consistently spacing our fasteners every 12-18 inches is critical. This prevents the lattice from flapping or tearing loose in strong gusts, which are not uncommon in places like Midwest City or Norman.

Potential Drawbacks and How to Avoid Them

Even with the best intentions, some challenges can arise. Being aware of them helps us avoid potential headaches.

- Fastener Degradation: As mentioned earlier, not all fasteners are created equal. Using non-UV-resistant plastic zip ties, for example, can lead to them becoming brittle and breaking down after just a few months of sun exposure. This can result in loose or detached lattice panels. We always recommend UV-resistant black zip ties or metal alternatives like stainless steel wire for longevity.

- Existing Fence Condition: If our existing chain link fence is already compromised (rusting, leaning, or damaged), attaching lattice will only exacerbate these issues. The added strain could lead to premature failure of the entire fence. It’s crucial to ensure the existing fence is in good, stable condition before we begin our lattice project.

- Aesthetic Discrepancies: While vinyl lattice is fantastic, sometimes the transition from an older, weathered chain link can be jarring. Consider cleaning and potentially repainting (if it’s a coated chain link) the existing fence components for a more cohesive look.

Checking Local Regulations

Before we pick up our tools, it’s always a good idea to do a quick check on local regulations. We wouldn’t want to invest our time and effort only to find out we’re not compliant!

- HOA Rules: If we live in a community with a Homeowners Association (HOA), there might be specific rules regarding fence modifications, materials, colors, or even the addition of lattice. It’s always best to consult our HOA guidelines first.

- City Ordinances on Fence Height: Many cities, including those in the OKC Metro area like Edmond or Moore, have ordinances that dictate maximum fence heights. If our plan is to add lattice to increase the height of our fence, we must verify that this addition falls within the legal limits. It’s wise to check local building codes with our city planning office to ensure our project is compliant and avoids any future headaches or fines.

Frequently Asked Questions about Attaching Vinyl Lattice

We get a lot of great questions about enhancing fences, and attaching vinyl lattice to a chain link fence is a popular topic. Here are some of the most common inquiries we receive:

What is the easiest and most removable way to attach vinyl lattice?

The easiest and most temporary method for attaching vinyl lattice, which also offers good removability, is to use heavy-duty, UV-resistant zip ties. These fasteners are incredibly simple to install: just thread them through the openings in the lattice and around the chain link mesh, then pull them tight. If we ever need to remove the panels—perhaps for maintenance, to access something behind the fence, or if we decide to change the look—we can simply snip the zip ties with a pair of cutters. They’re affordable, readily available, and make the installation and removal process quite straightforward. Just remember to use black zip ties, as they offer superior UV resistance compared to clear ones.

How does attaching vinyl lattice affect the fence in high winds?

Attaching lattice to a chain link fence significantly increases its surface area. This means that our fence will act more like a “sail” when strong winds blow, catching more air than a bare chain link fence would. This increased wind load puts considerably more stress on the fence posts and the overall structure of the chain link fence.

It is absolutely crucial that our existing chain link fence is structurally sound and its posts are firmly anchored, especially if we’re in an area known for high winds like much of Oklahoma. If the posts are loose, leaning, or not deeply set, the added pressure from the lattice could cause them to fail. To mitigate this risk, we recommend:

- Ensuring Sturdy Posts: Inspect our fence posts thoroughly before installation. If they seem weak, consider reinforcing them.

- Secure Fastening: Regardless of the attachment method, ensure the lattice is securely fastened at frequent intervals—every 12-18 inches around the perimeter and at intermediate points—to distribute the load and prevent the panels from tearing loose.

- Considering a Frame Method: For maximum wind resistance, the frame method (as discussed in Step 3) provides a more rigid structure that can better withstand severe gusts.

Can I attach vinyl lattice to add height to my fence?

Yes, it is possible to attach vinyl lattice to add height to an existing fence, but this requires careful planning and adherence to regulations. If our goal is to extend the height of our fence, here’s what we need to consider:

- Structural Stability: Just like with wind resistance, adding height means adding more leverage and stress on our fence posts. We must ensure our fence posts are exceptionally stable and strong enough to support the extra height and any additional wind load this creates. We might need to extend the existing posts with post extensions or reinforce them.

- Local Regulations: This is perhaps the most critical step. Many cities and HOAs in areas like Oklahoma City, Norman, and Edmond have strict rules regarding maximum fence height. Before we add any height, we must check with our local city planning office and HOA to confirm that our proposed new fence height is compliant. Failing to do so could result in fines or being forced to remove the addition.

- Aesthetic Integration: When adding height, consider how the lattice will integrate visually with the existing fence. We want it to look like a cohesive part of the fence, not an afterthought.

Conclusion

Attaching vinyl lattice to a chain link fence is a fantastic and accessible way to transform our outdoor living space. We’ve explored the myriad benefits, from the instant aesthetic upgrade and improved privacy to the long-term durability and low maintenance that vinyl offers. We’ve walked through the essential tools and materials, and detailed both the direct attachment and the more robust frame method, ensuring we’re equipped for success.

While this project is a rewarding DIY endeavor, we’ve also highlighted crucial considerations like managing wind load, preventing common pitfalls, and the ever-important step of checking local regulations in our Oklahoma communities.

This project is more than just attaching panels; it’s about creating a more beautiful, private, and enjoyable outdoor environment. It’s a rewarding DIY project that dramatically improves our outdoor space. If we decide a professional touch is what we need, explore our professional vinyl fence installation services. For more complex fencing needs or a brand new vinylfence, the experts at A Better Fence Construction are always here to offer professional guidance and meticulous installation, ensuring lasting quality and client satisfaction.